Cement Production Process Flow Diagram Photos

11.6.1 Process Description1-7 Portland cement is a fine powder, gray or white in color, that consists of a mixture of hydraulic cement materials comprising primarily calcium silicates, aluminates and aluminoferrites.

Portland Cement Flowchart Process Flow Diagram Manufacturing PNG, Clipart, Angle, Area, Brand

Download scientific diagram | CEMENT MANUFACTURING PROCESS FLOW CHART from publication: Industrial Geology | | ResearchGate, the professional network for scientists.

1 Simplified schematic flow chart of the dry process of manufacturing... Download Scientific

Process flow diagram for the cement manufacturing process, showing electricity and heat consumption or inputs [39]. Source publication Energy Savings Associated with the Use of Fly Ash and.

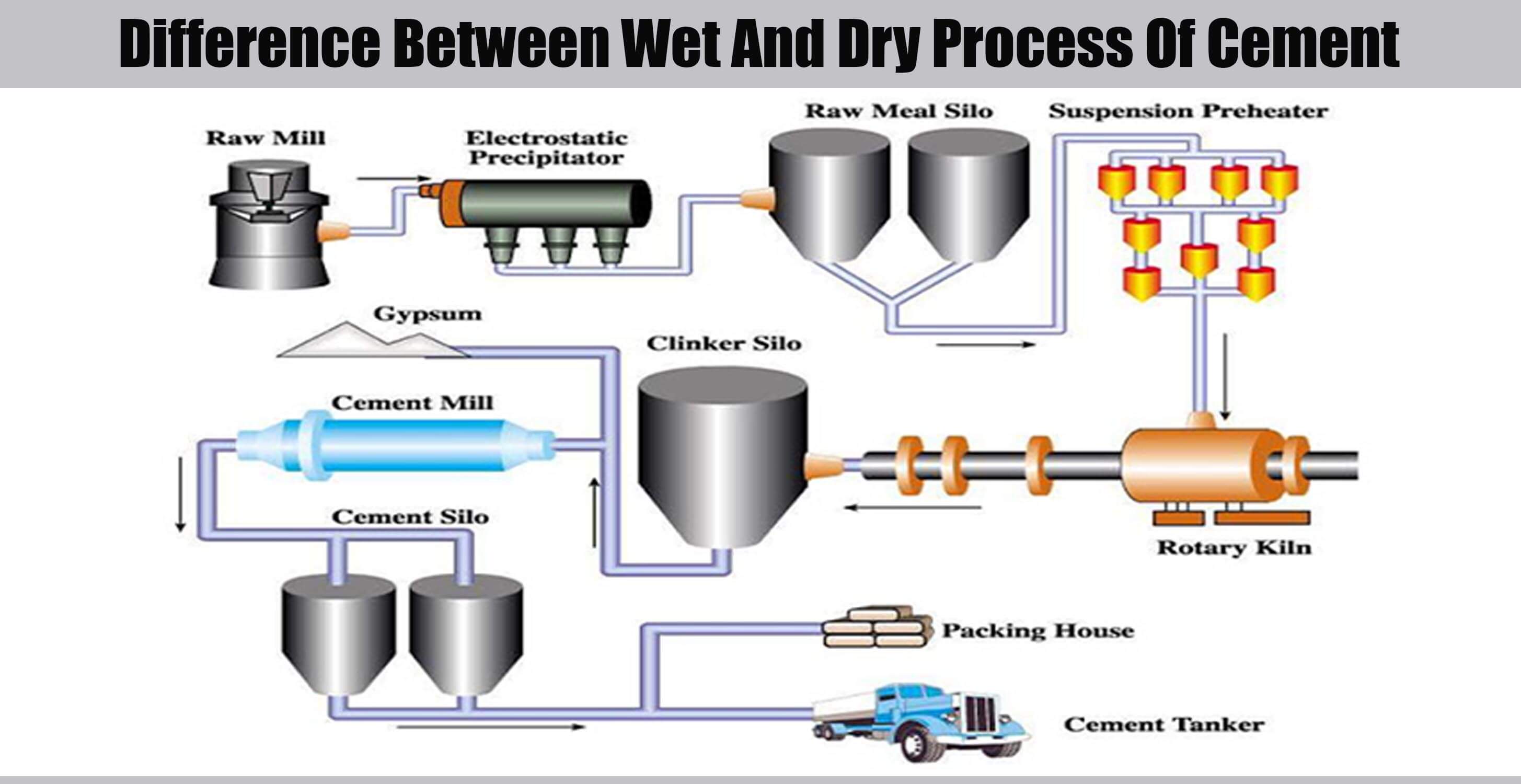

2 Process Of Manufacture Of Cement Wet Process & Dry Process Of Cement Manufacture Civil Giant

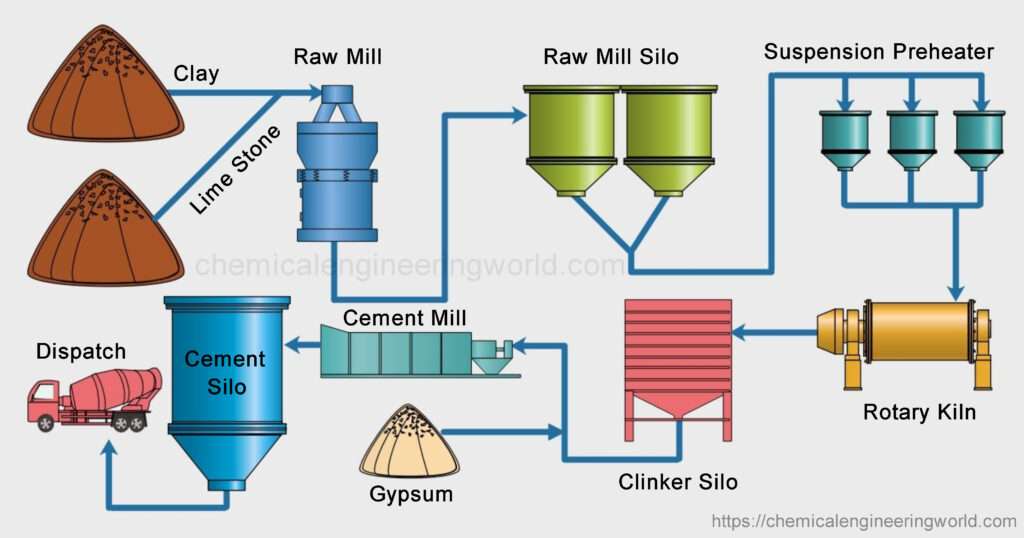

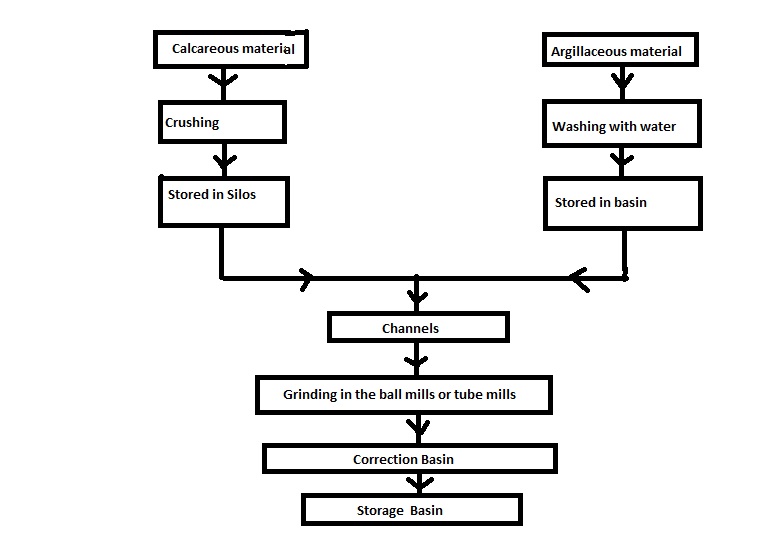

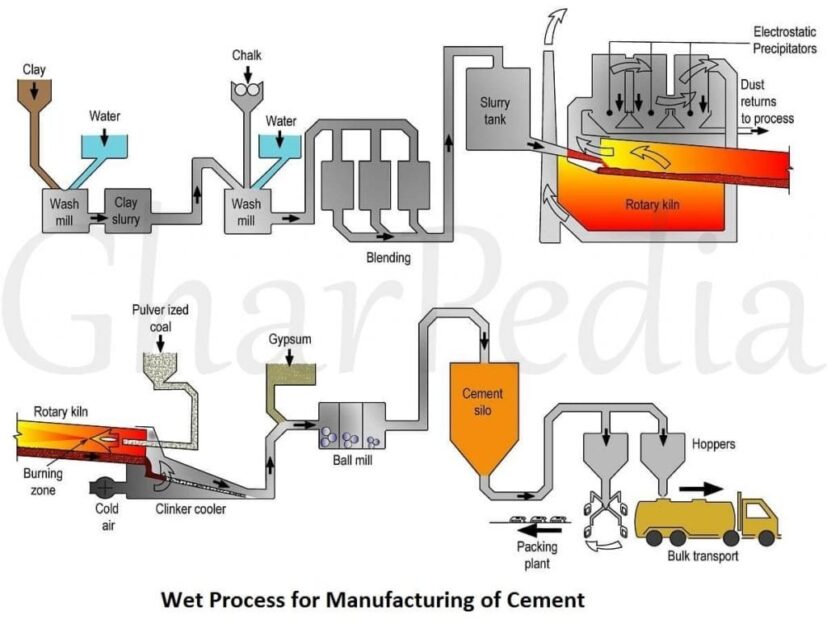

Cement manufacturing is a complex process that begins with mining and then grinding raw materials that include limestone and clay, to a fine powder, called raw meal, which is then heated to a sintering temperature as high as 1450 °C in a cement kiln.

What is Cement and How it is Manufactured? The Machine Design

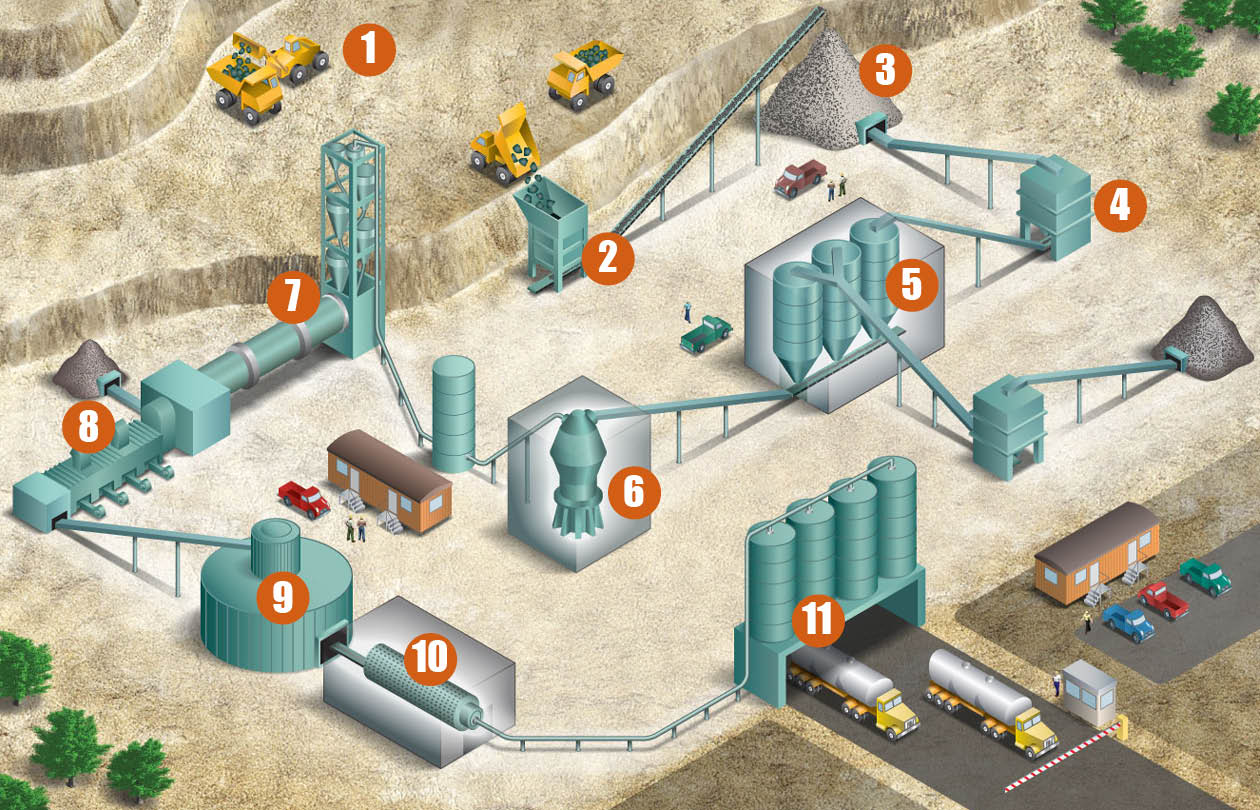

A. Cement manufacturing Process Source:civilengineeringforum.me. As can be seen in Fig 1 (Process and Quality flow diagram) above, there are around 8 quality check points where by different samples are taken at some time interval (every hour most of the time) to check whether the raw materials/intermediate.

Cement Process Map

Cement manufacturing process - components of a cement plant from quarry to kiln to cement mill. Skip to content. Menu. Home; Resources. Civil PowerPoint Presentations | Civil ppts; Interview Questions;. Cement Manufacturing Process Simplified Flow Chart. March 15, 2017 May 11, 2013 by Johnny.

Process Flow Diagram of the Cement Plant Download Scientific Diagram

The flow diagram of mixing of raw materials by dry process. Flow diagram of dry process cement. Wet process ( old technology ) In the earlier part of the century i.e., from 1913 to 1960, the wet process was used for the manufacture of cement. From 1913 onwards, the cement industry underwent a number of changes mainly to suit the requirements of.

Manufacturing of Portland Cement Process and Materials Cement Concrete

Cement Manufacturing Process Flow Chart (i) Drying Zones: In the wet process, the drying zone is comparatively larger than the dry process. It is because the raw material in slurry form is directly fed into the kiln which has more amount of water. As shown in the figure it is the upper portion of the kiln.

Difference Between Wet And Dry Process Of Cement Engineering Discoveries

Cement Manufacturing Process Flowsheet (Flow Chart) Source publication Cement Manufacturing - Process Modeling and Techno-Economic Assessment (TEA) using SuperPro Designer. Preprint.

Cement Production Process Flow Diagram Photos

A cement process flow diagram (PFD) is a graphical representation of the main steps and equipment involved in producing cement from raw materials. It can help you understand how the process.

Civil Engineering materials. Wet process Cement manufacturing Flow Diagram

Context 1. 40% of the CO 2 comes from fossil fuel combustion in the kiln process, about 50% is due to de-carbonation of limestone (CaCO 3 ) to calcium oxide (CaO), and the remaining 10% is.

cement clinker manufacturing processing plant linxiaomoのblog

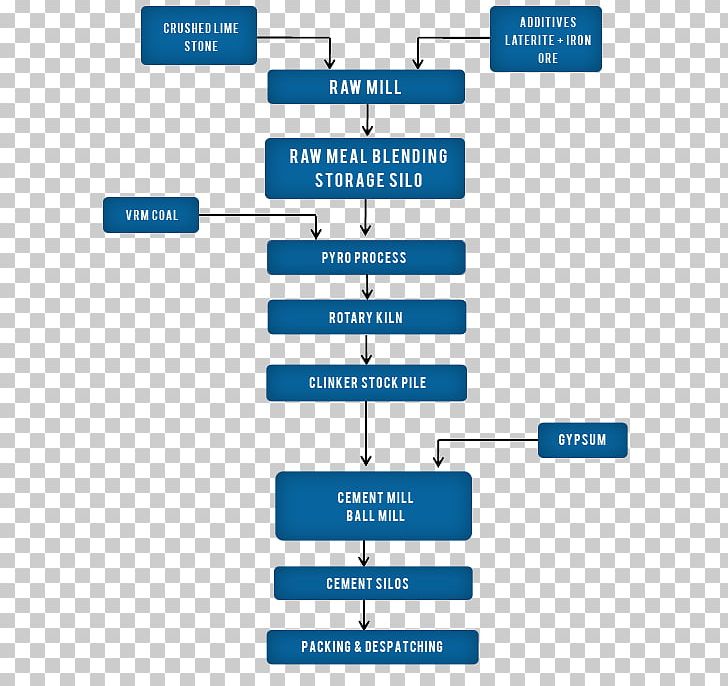

In this study the process flow diagram for the cement production was simulated using Aspen HYSYS 8.8 software to achieve high energy optimization and optimum cement flow rate by varying the flow rate of calcium oxide and silica in the clinker feed. Central composite Design (C.C.D) of Response Surface Methodology was used to design the ten experiments for the simulation using Design Expert 10.0.3.

Cement Manufacturing Process

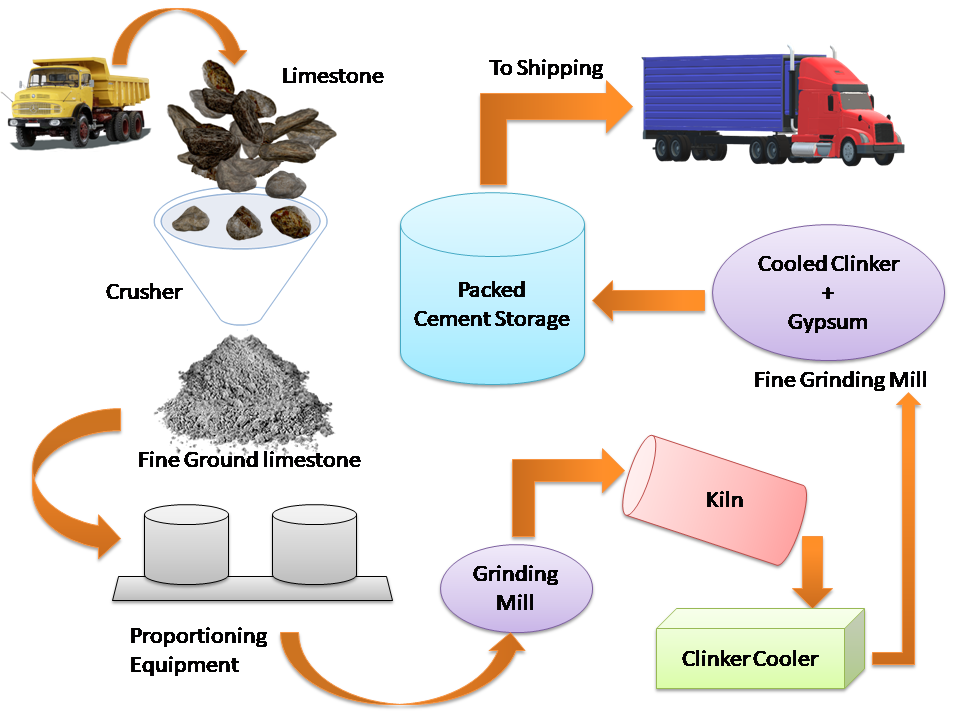

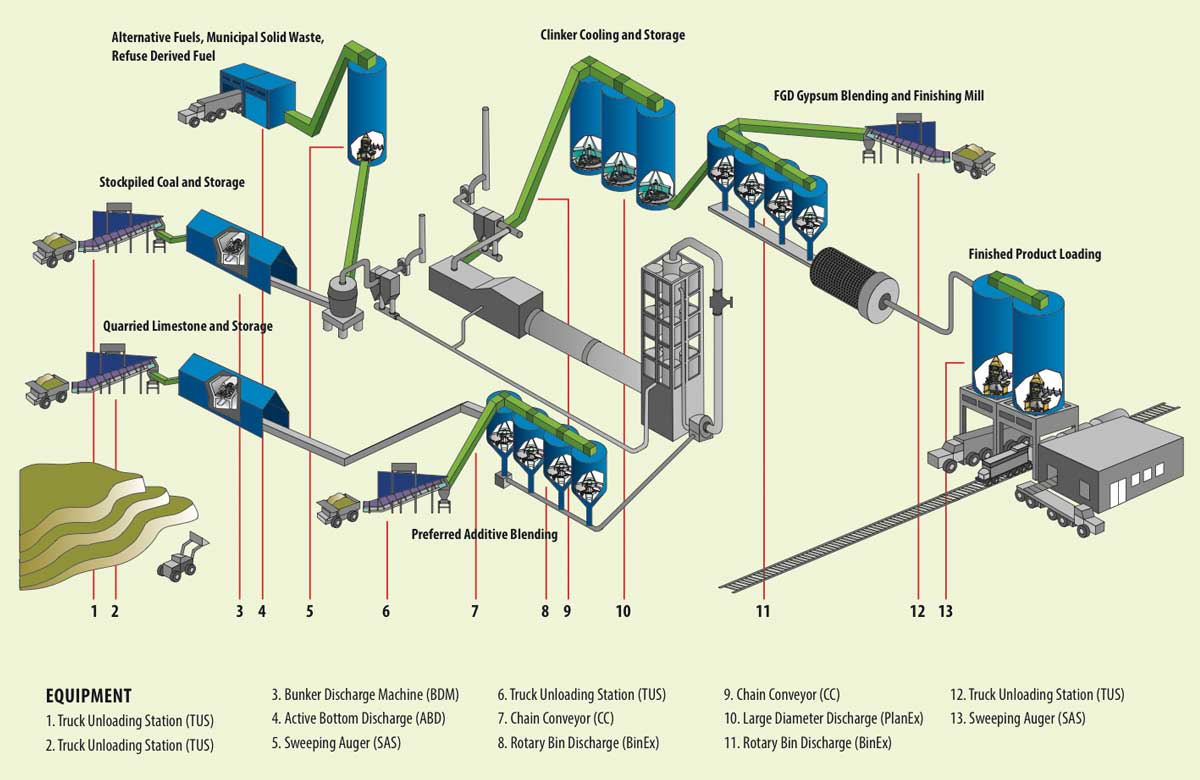

There are six main stages of the cement manufacturing process. Stage 1: Raw Material Extraction/Quarry The raw cement ingredients needed for cement production are limestone (calcium), sand and clay (silicon, aluminum, iron), shale, fly ash, mill scale, and bauxite. The ore rocks are quarried and crushed into smaller pieces of about 6 inches.

Process flow diagram for the cement manufacturing process, showing... Download Scientific Diagram

Cement Manufacturing Process Phase 1: Raw Material Extraction Cement uses raw materials that cover calcium, silicon, iron and aluminum. Such raw materials are limestone, clay and sand. Limestone is for calcium. It is combined with much smaller proportions of sand and clay. Sand & clay fulfill the need of silicon, iron and aluminum.

DETAILED MANUFACTURING PROCESS OF CEMENT lceted LCETED INSTITUTE FOR CIVIL ENGINEERS

A diagram of the process, which encompasses production of both portland and masonry cement, is shown in Figure 11.6-1. As shown in the figure, the process can be divided into the following primary components: raw materials acquisition and handling, kiln feed preparation, pyroprocessing, and finished cement grinding.

Cement Notes Class 12 Applied Chemistry Unit 19 NEB Notes

1) Mixing of raw materials 2) Burning 3) Grinding 4) Packing of cement Flow chart for manufacturing of cement Table Of Contents Mixing of raw materials: The processes used for the manufacture of portland cement can be classified as dry and wet. In dry process.