9 Types of Cooling Tower Fills from Manufacturer in China Sara Cooling Tower

The "fill" is the most important component in a cooling tower — it's where all the action to provide adequate cool water takes place. When the fill is in good condition and clean, it will provide the amount of cooled water that the tower was designed provide; if the fill is it damaged, plugged, or missing, the tower will not produce adequate cooling water.

Round Cooling Tower Fills Low Price from Manufacturer in China Sara Cooling Tower

Cooling tower nozzles direct the hot water in need of cooling to the tower fill. Brentwood's spray nozzles are located and sized in order to provide a uniform pattern of water over the fill with no gaps between their spray areas. This enables the fill to be fully wetted out and ensures high performance. Explore Nozzles

Black PVC Cooling Tower Fills at Rs 100/piece in Mumbai ID 21950618997

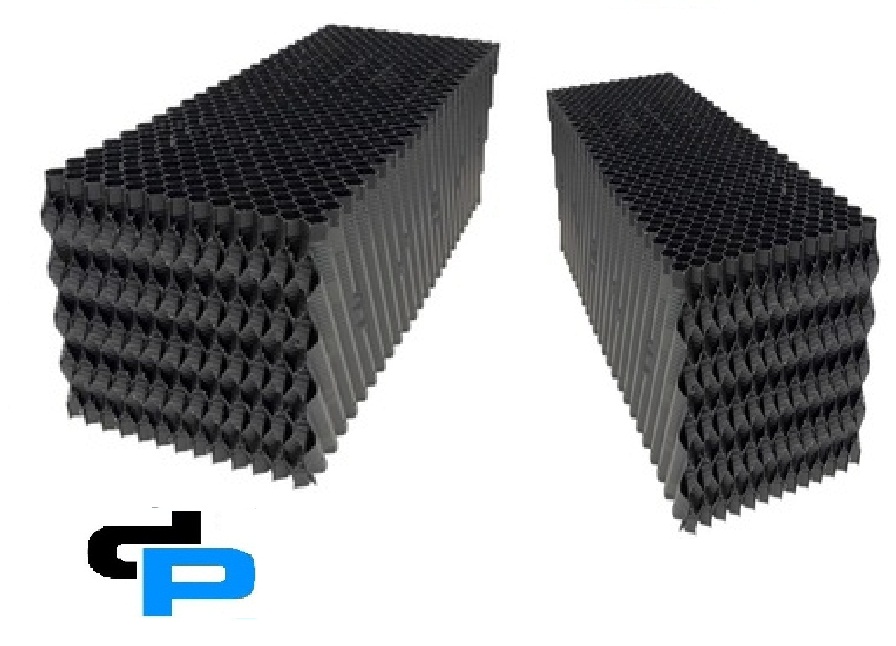

Film fill comes in sheets of material, shaped into a corrugated pattern. This pattern enables the water to travel across it smoothly and quickly. To create various thickness and heights, this fill can be stacked. In other words, film fill can be customized to fit the needs of any particular cooling tower. This type of fill is the most popular.

PVC Cooling Tower Fills by Nizza Plastic Co., Ltd, PVC Cooling Tower Fills ID 3175485

The Role of a Fill in the Cooling Process. The term "fill" refers to the medium used to create a greater surface area for water passing through the tower to be cooled. Fills are also sometimes called wet decks or fill mediums. More surface area means contact between airflow and water is maximized, leading to quicker evaporation and.

Europack Black And Blue PVC Cooling Tower Fills, Packaging Type Gunny Bag, Packaging Size

Cooling tower sheet fills or media, come in many different forms and "micro-structures," each having unique characteristics to fit various applications. Film fills are selected for direct replacement, performance enhancement, and water condition compatibility. Each fill has performance characteristics that allow selections to be made for.

Cooling Tower Fill Types

Keep in mind that the process of testing this new section of fill requires some forethought so that you have the fill "soaking" for a year or longer prior to needing a full fill replacement. This process is needed so that the fill sees all variability in the water quality, such as seasonal changes for a cooling tower utilizing river water.

Sigma Cooling Tower Fills Manufacturer in Delhi India by Dp Engineers ID 760496

Cooling tower fill material plays a vital role in the operation of cooling towers. It refers to the medium through which the hot water from industrial processes is cooled down by the process of evaporation. The fill material increases the surface area available for heat transfer, facilitating the exchange of heat between air and water.

Round Cooling Tower Fills Low Price from Manufacturer in China Sara Cooling Tower

the fact that splash-fill is seldom used in counterflow cooling towers. Because of the water dispersal that takes place, splash-fill cooling . towers are far more forgiving of the poor initial water distribution which can result from clogged or missing nozzles, than are film-fill cooling towers. The splashing action effectively redistributes the

PVC Cooling Tower Fills at Rs 130/piece Pvc Cooling Tower Fills in Vasai ID 12677552155

Cooling tower fills are a key component of cooling towers. It increases the heat dissipation, extends the retention time of the cooling water and enlarges the effective surface area, making its temperature drop accounting for 60%-70% of the entire cooling tower. Fills largely determine the circulating water-cooling effect.

PVC Cooling Tower Fills Polyvinyl Chloride Cooling Tower Fills Latest Price, Manufacturers

Cooling tower is a heat exchanger or heat rejection device, inside of which heat is discharged from the water by contact between the water and the air. Hot water from the system enters the cooling tower and is distributed overspread the fill, through which the air is forced, causing a small portion of the water to evaporate.

Cooling Tower Fill,Cooling Tower Accessory,Water Treatment Media

Herringbone Fills. Herringbone fills take advantage of an engineered surface design to distribute water evenly over the entire fill area for high thermal performance. These fills are designed to replace OEM hanging fill sheets in crossflow cooling towers serving HVAC, light industrial, and other process cooling requirements.

Cooling Tower Fill for FactoryAssembled Towers 20180416 Process Cooling

Film Fills are the most efficient filling media available for cooling towers. The usage of film fills - in both counterflow and crossflow cooling towers allows relatively smaller sized towers to cool an equivalent amount of water compared to cooling towers using splash fills. This results in the saving of not only capital costs for a new.

Black Cooling Tower PVC Fills, For Industrial, Packaging Type Packet, Rs 100 /piece ID

By Brad Buecker. C ooling towers are a key component at industries around the globe. Proper chemistry control is essential for steady heat transfer in towers and their physical stability as well. But even with diligent chemical feed and monitoring, cooling towers, and especially the tower fill, can accumulate scale and microbiological deposits that inhibit heat exchange and, in worst case.

COOLING TOWER FILLS APPLICATION Sinta FRP Focus on Quality

Most cooling towers now utilize film fill to enhance air/water contact. Film fill, as the name implies, induces the cooling water to form a film on the material surface. The filming mechanism maximizes liquid surface area. A guiding principle behind fill design and selection "is to increase air-to-water contact, driving up convection and.

Anew Tower Tech Black and Blue and White Cooling Tower Fills at Rs 3500/piece in Navi Mumbai

Cooling tower fill is a medium that's used to increase the surface area available for the water. Below is a breakdown of the most common fill types used in cooling towers today. Splash Fill. This cooling tower fill type will cause the water to cascade through a large series of parallel bars. The water will then redistribute at each bar level.

Cooling Tower PVC Fills at Rs 155/piece PVC Cooling Tower Fills in Yamuna Nagar ID 10973770388

The cooling tower is essentially just a box built to contain the water to be cooled. Because the water is cooled via the evaporative heat and mass transfer of water, the box has components that enhance that mechanism, such as air-moving equipment and components that improve the interactions of air and water, namely "fill.".